Image credit popular mechanics at: www.popularmechanics.com

Only have a plastic printer? No worries... you can still create functional metal parts.

This article runs through how we use an SLA (RESIN based) printer to produce metal parts… As always If you have questions, comments, or would just like to chat about 3D printing, feel free to get ahold of us through the comment section at the bottom of this page or through one of our social media outlets.

3D PRINTING CASTABLE WAX (LOST-WAX CASTING)

We are talking about Investment casting which dont get me wrong. Investment casting has been used for millennia. However, now we are merging the technology with Additive Manufacturing in order to create some of the most beautiful yet highly functional parts that just couldnt be made or at least weren’t even remotely affordable a short time ago. In the last few years 3D printing with castable wax resin has became an awesome way to reduce your Prototyping Expense & Labor for that matter. Especially considering the fact that every day more and more companies are using “Generative Design” techniques in order to reduce weight while still maintaining the strength of the parts machined from billet. The problem most machining companies are faced with is simple. COST to produce actual part at it’s optimal design. The fact is in some cases these designs cannot even be made with conventional subtractive manufacturing methods alone. Some parts you can look at now and immediately your mind jumps to Metal Additive Manufacturing / 3D printing technology. However, today I am here to talk to you about another way.

Image and great article with similar subject can be found at: https://www.ennomotive.com/3d-printing-metal-parts/

Additive manufacturing is becoming more and more reliable and changing efficiancies, profitability and even the saftey of entire industries. More and more businesses are adapting their workflow to include additive. The technnology is in dentistry everywhere. Chances are your grandparents dentures or even your crown has had a 3D printer involved with producing or at least prototyping them. Medical fields in general have been making the switch for metal and even casts for broken bones etc… Yet, up to this point 3D printing castable wax parts in the jewlery sector is king. Nowadays, if you get yourself a small desk top 3D printer you can produce and even sell some jewlery online via etsy, amazon etc… Often the designs are unique 1 of a kind organic designs that really have changed the jewlery landscape.

WORK FLOW for LOST-WAX CASTING PROTOTYPE

Image and great article with similar subject can be found at: https://formlabs.com/industries/jewelry/

Sky high machine costs and high material costs involved with metal additive manufacturing… 3D printing at the moment can stil prove to be a tough pill to swallow. The fact remains additive manufacturing is absolutely perfect for Generative designed parts. Which generative designed parts are gaining headway in many industries that are starting to see benefits. In aerospace industry losing 1 lb per commercial airline seat can account for billions of dollars in fuel saved over the life of the fleat. Lost-wax casting is not perfect for every industry but it can be a way of getting metal prototypes now…for less up front cost. The surface finish can also be your guide as to which direction you should take. Metal 3D printed parts generally have a rough surface finish that would require subsequent operations to get them smooth. If your looking to buy your own printer the base price of resin printers is way lower and can still offer you a way of getting the job done. It can almost be a first step into 3D printing metal parts.

PROOF 3D PRINTING CASTABLE WAX RESIN IS VIABLE

As a case in point I have included a short video that was done by a collaboration between Formlabs and Golden Century Casting. A premium jewlery designer that uses Formlabs Printers to produce 99% of the jewlery they make. I include it not because you or I are looking to get into jewlery making but I think it allows you to understand what is possible. What is already happening and most importantly what is not going away.

Along with the video below are links to the companies sites: https://formlabs.com/industries/

https://www.goldencenturycasting.com/

More on SLA (Stereolithography)

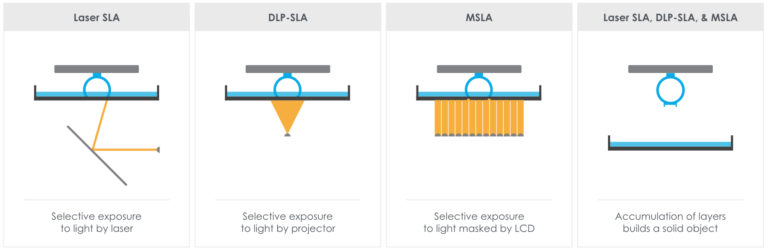

SLA v DLP v MSLA image credit: Formlabs www.formlabs.com

Please leave a comment below with any questions or suggestions to make our future posts even better!