Explaining the different nuances of some Additive Manufacturing (3D printing) technologies.

This article will run through three of what are considered to be the most popular 3D printing methods. If you have questions, comments, or would just like to chat about 3D printing, feel free to get ahold of us through the comment section at the bottom of this page or through one of our social media outlets.

SLS (Selective Laser Sintering)

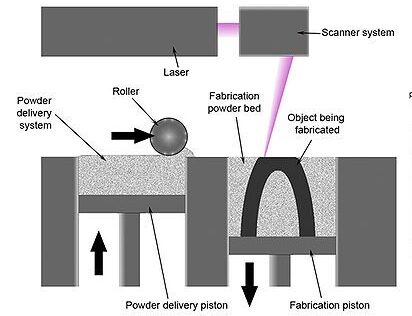

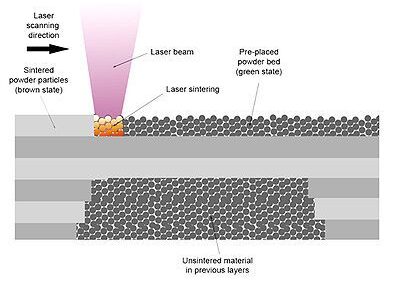

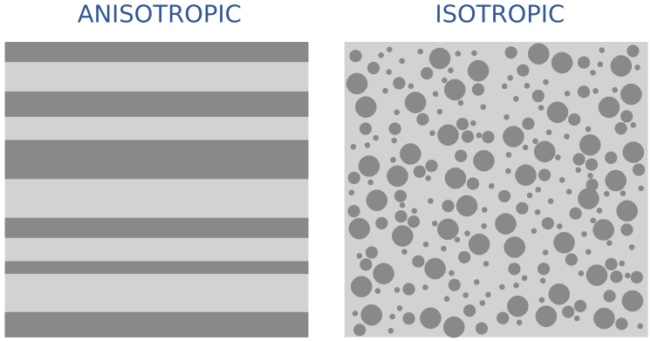

For anyone looking to make long-term, mechanically-sound functional parts, SLS is about as good as it gets. The SLS (Selective Laser Sintering) process is used primarily in industrial applications as the machines are typically outside of the justifiable price range for most small businesses and DIYers. That being said, typically this method produces some of the best isotropic mechanical properties achievable in 3D printing. However, it unfortunately is not the fastest process. In SLS, a thin layer of powder is dispersed onto the build platform usually ~.1mm or less in height depending on the application and machine. The powder material is sintered by the laser, and the build plate then lowers by the specified layer height (~.1mm). A new layer of powder is then redistributed and is then sintered to the previous layer. Figure A below shows a simplistic example of a SLS machine. While figure B shows a close up view of the powder pellets melting into a solid layer.

Figure A

Figure B

This method of printing is advantageous for a couple of reasons. For instance, because the powder that surrounds the part essentially holds the part suspended in place, it is capable of producing parts without the need for a support structure. This also allows for the entire build volume to be packed with parts very close together. In many cases, multiple parts of an assembly can be produced fully assembled right out of the printer. Below I have embedded a short YouTube video from my channel SKĒM-INC to subscribe click here!

SLA (Stereolithography)

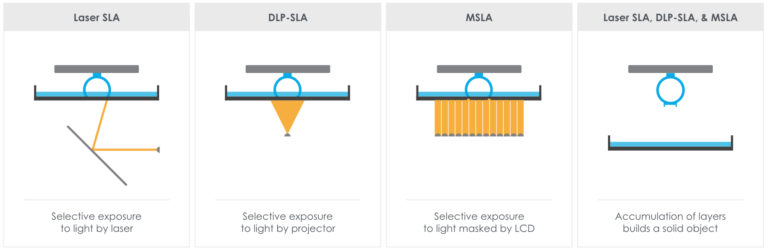

SLA v DLP v MSLA image credit: Formlabs www.formlabs.com

FDM (Fused Deposition Modeling)

That being said, FDM can boast many positives. For instance, FDM is safer, easier to use, and makes it much easier to handle materials. Typically, FDM uses a Filament Spool. This is a 1.75~3mm diameter extrusion that is wrapped in 1-5kg spools of material. There are no harsh chemicals used in the process, and in most cases not even a bad smell. It is basically functioning like a hot glue gun.

Hot Glue Gun image credit: Gorilla Glue www.gorillatough.com

Hot Glue Gun image credit: Gorilla Glue www.gorillatough.com

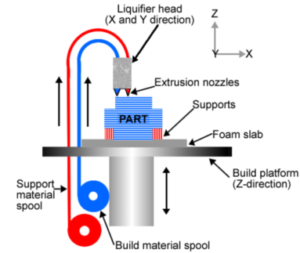

In the FDM process, the spooled material gets threaded through the machine and is eventually pushed into a heated block causing it to melt as it nears the exit of the nozzle. The melted filament is then deposited on a build platform eventually creating a layer of the part. This method generally ranges from the .1~.8mm layer height. Below is an illustration that also depicts the supports in red. It is possible for this support material to be different from the part material if you have at least a dual extruder machine. In some cases, the support material can even be soluble allowing for very easy removal of the supports after the part is completed.

The principle of FDM method [Thai3dprint 2012]

Many FDM machines on the market today have a heated build platform. This helps the material adhere to the surface of the build plate and reduces warpage etc. Common materials that are used in FDM printing consist of PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), TPU (Thermoplastic Polyurethane) etc. It should be noted that there are seemingly limitless other varieties and blends of materials that have already been developed as FDM has risen to fame. This method is by far and away the best starting point for most 3D hobbyists and businesses (including myself). This video from i.materialize is a time lapse video demonstration of the technology.

To visit i.materialise YouTube channel click on this link below:

Please leave a comment below with any questions or suggestions to make our future posts even better!